Material collection

Each machine has its own shape and functionality and generates waste from completely different shapes and sizes. Before aerating efficiently, it is essential to make aerodynamic hoods and nozzles that ensure the homogeneous and effective collection of the material.

Aspiration

In the aluminum sector it is possible to use both types of suction: the original tearing fan, able to suck up trimmings up to a speed of 1,200mt / min with a transport up to 100mt; the exclusive injector recently updated to guarantee lower energy consumption and low acoustic impact, as well as guaranteeing performance up to 1000 m / min. The trimming, transported continuously without being chopped, can be conveyed into a round baler.

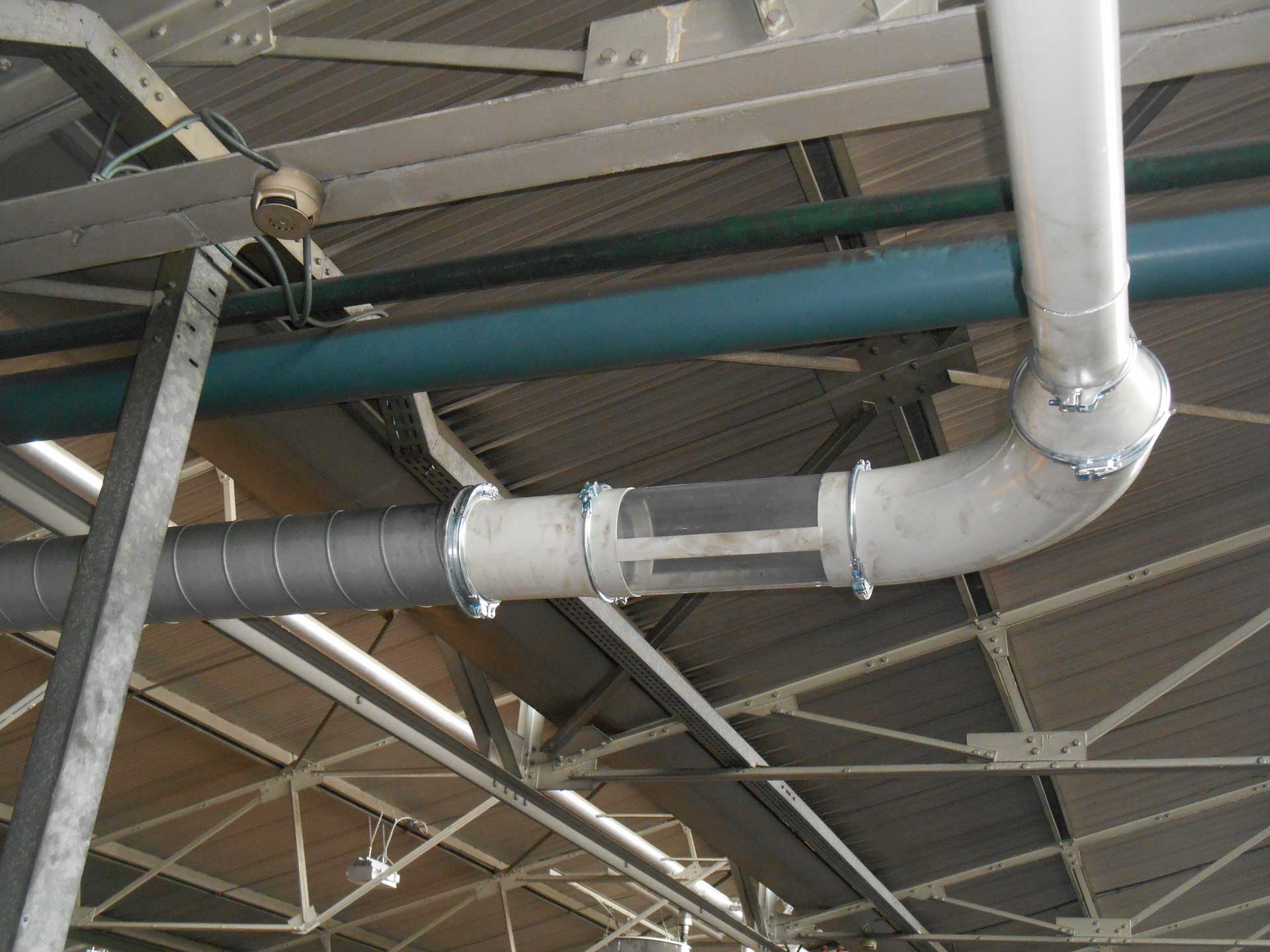

Transport

Nothing is left to chance ... New Aerodinamica has conducted accurate market research by selecting the best suppliers in the industry to ensure the supply of the best materials. The transport pipes are top of the range in painted iron or stainless steel, depending on the installation. This type of pipes, in addition to having higher thicknesses, sealing joint systems and being completely smooth inside greatly improve flows, performance and eliminate any risk of blockage of material.

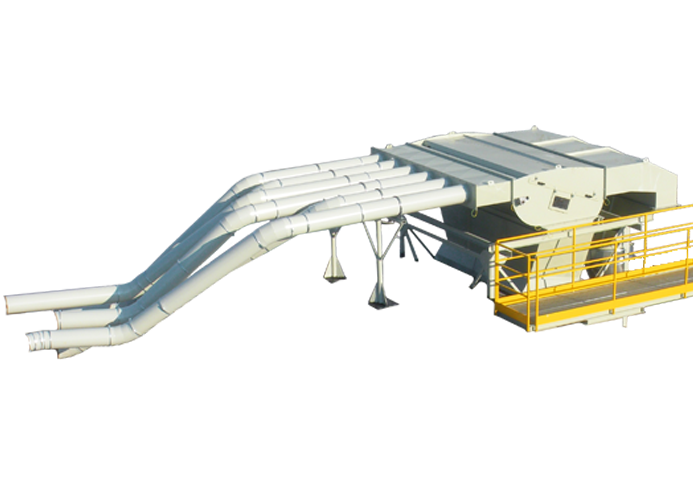

Separation

The transported material is discharged through aerodynamic separator sized for the total volume of air, this equipment works without the aid of mechanical sealing elements as it is kept in perfect balance with balancing fans.

Depending on the type of material are inserted specific accessories.

.jpg)